Bestway Bags- One stop solution service provider for all kinds of Leather Bags, Handbags And Briefcases

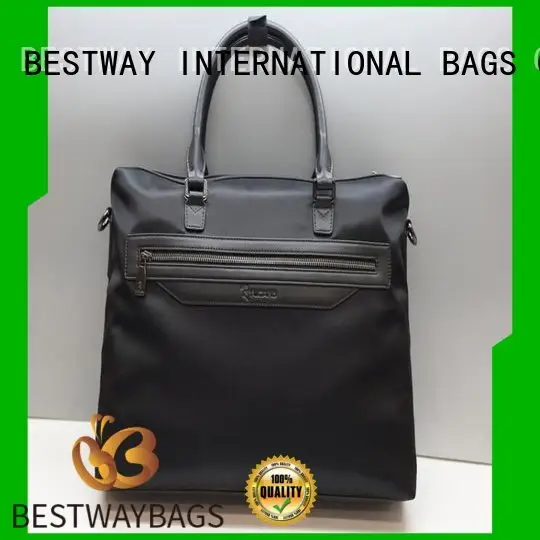

Bestway handle nylon shoulder bag personalized for sport

Brand:

BESTWAY

Model:

BYW-N098

Product type/style:

Laptop bag

Shell material:

nylon with leather material

Inner material:

100% polyester

MOQ:

200pcs/style

Supply Ability:

30000PCS per month

Payment:

T/T, L/C, PayPal, Western Union

Port:

200pcs/style

Delivery Time:

25-45days after received deposit

Price term:

FOB, EXW, CIF

Company Advantages

1. Bestway is done through several basic processes. It will be cut, sewn, fiber washed, dyed and decorated. The product is capacious and can store much stuff

2. A high reputation of Bestway Bags has been formed among manufacturers and users. The product features fine breathability, which prevents the things in it from getting too moist or too dry

3. nylon shoulder bag is not only tough and durable, but also . Logos can be customized on the product using the emboss, foil printing, or embroidery method

Company Features

1. Always aim high in quality of nylon shoulder bag .

2. Thanks to the enterprise culture of Bestway, we all aim to strive forward at one direction. Please contact.

1. Bestway is done through several basic processes. It will be cut, sewn, fiber washed, dyed and decorated. The product is capacious and can store much stuff

2. A high reputation of Bestway Bags has been formed among manufacturers and users. The product features fine breathability, which prevents the things in it from getting too moist or too dry

3. nylon shoulder bag is not only tough and durable, but also . Logos can be customized on the product using the emboss, foil printing, or embroidery method

Company Features

1. Always aim high in quality of nylon shoulder bag .

2. Thanks to the enterprise culture of Bestway, we all aim to strive forward at one direction. Please contact.

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Contact us

we welcome custom designs and ideas and is able to cater to the specific requirements. for more information, please visit the website or contact us directly with questions or inquiries.

you might like

no data